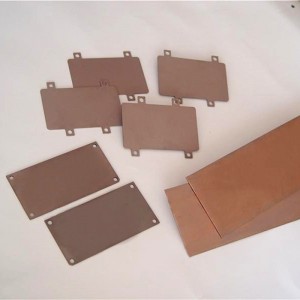

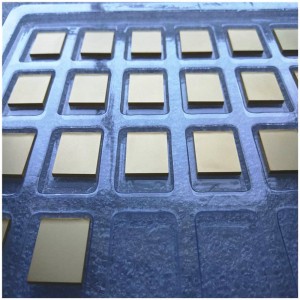

Tungsten Copper WCu Heat Sink

wehewehe

Loaʻa i nā mea hoʻopihapiha uila keleawe ʻo Tungsten ka haʻahaʻa haʻahaʻa haʻahaʻa o ka tungsten a me nā waiwai conductivity thermal kiʻekiʻe o ke keleawe. ʻO ka mea nui loa, ʻo ia ka hiki ke hoʻolālā ʻia ka mea hoʻonui wela a me ka conductivity thermal ma o ka hoʻoponopono ʻana i ke ʻano o ka mea i lawe ʻia i ka maʻalahi.

Hoʻohana ʻo FOTMA i ka maʻemaʻe kiʻekiʻe a me ke ʻano kiʻekiʻe, a loaʻa iā WCu nā lako uila uila a me nā mea wela me ka hana maikaʻi loa ma hope o ke kaomi ʻana, ka sintering kiʻekiʻe a me ka infiltration.

ʻO nā pono o ka Tungsten Copper (WCu) Electronic Packaging Materials

1. ʻO ka tungsten copper electronic packaging material he adjustable thermal expansion coefficient, hiki ke hoʻohālikelike ʻia me nā substrates like ʻole (e like me: stainless steel, valve alloy, silicon, gallium arsenide, gallium nitride, aluminum oxide, etc.);

2. ʻAʻole hoʻohui ʻia nā mea hoʻonā sintering e mālama i ka conductivity thermal maikaʻi;

3. Haʻahaʻa porosity a maikaʻi ea tightness;

4. ʻO ka mana nui maikaʻi, ka hoʻopau ʻana i ka ʻili a me ka palahalaha.

5. Hāʻawi i ka pepa, nā ʻāpana i hana ʻia, hiki ke hoʻokō i nā pono o ka electroplating.

Kopa Tungsten Heat Sink Pono

| Papa Mea | Maʻiʻo Tungsten Wt% | ʻO ka mānoanoa g/cm3 | Hoʻonui wela ×10-6CTE(20℃) | ʻO ka hoʻoheheʻe wela W/(M·K) |

| 90WCu | 90±2% | 17.0 | 6.5 | 180 (25 ℃) /176 (100 ℃) |

| 85WCu | 85±2% | 16.4 | 7.2 | 190 (25 ℃)/ 183 (100 ℃) |

| 80WCu | 80±2% | 15.65 | 8.3 | 200 (25 ℃) / 197 (100 ℃) |

| 75WCu | 75±2% | 14.9 | 9.0 | 230 (25 ℃) / 220 (100 ℃) |

| 50WCu | 50±2% | 12.2 | 12.5 | 340 (25 ℃) / 310 (100 ℃) |

No ka hoʻohana ʻana o Tungsten Copper Heat Sinks

Nā mea kūpono no ka hoʻopili ʻana me nā mea mana kiʻekiʻe, e like me nā substrates, nā electrodes haʻahaʻa, etc.; nā papa alakaʻi kiʻekiʻe; nā papa hoʻomalu wela a me nā radiators no ka pūʻali koa a me nā mea hoʻokele wela kīwila.