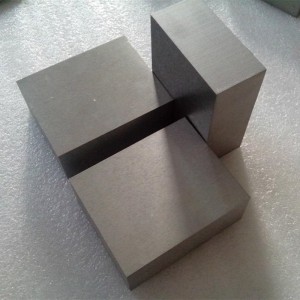

ʻAiʻa Tungsten kala

ʻO ke kala tungsten alloy kahi hui kūʻokoʻa o nā metala kupaianaha ʻelua, ke kālā a me ka tungsten, e hāʻawi ana i kahi hoʻonohonoho kūʻokoʻa o nā waiwai a me nā noi.

Hoʻohui ka alloy i ka conductivity uila maikaʻi loa o ke kālā me ka helu hoʻoheheʻe kiʻekiʻe, ka paʻakikī, a me ka pale ʻana o ka tungsten. He mea kūpono loa ia no nā noi koi ʻē aʻe i ka ʻenehana uila a me ka mechanical.

I ka ʻoihana uila, hoʻohana ʻia ke kala tungsten alloy i nā pili uila a me nā hoʻololi. ʻO kona hiki ke kū i nā wela kiʻekiʻe a me ka arcing e hilinaʻi ʻia i kēia mau mea koʻikoʻi. No ka laʻana, i nā ʻōnaehana uila mana kiʻekiʻe, kahi nui o ke kahe o kēia manawa a ʻoi aku ka nui o ka hopena o ka overheating, ʻo ka hoʻohana ʻana i ke kālā tungsten alloy e hōʻoia i ka hana pono a palekana.

Ma ke aupuni mechanical, loaʻa iā ia ka hoʻohana ʻana i nā mea hana a make ma muli o kona paʻakikī a paʻa. Hiki i nā ʻāpana i hana ʻia mai kēia huila ke kū i ke koʻikoʻi mechanical a me ka lole abrasive, e hoʻolōʻihi i ko lākou ola a hoʻomaikaʻi i ka hana.

Hoʻokomo pinepine ʻia ka hana ʻana o ke kala tungsten alloy i nā kaʻina hana paʻakikī e hoʻokō i ka haku mele a me ka microstructure makemake. Mālama kēia i ke koena kūpono o nā waiwai no nā noi kikoʻī.

Ke hoʻomau nei ka noiʻi ʻana a me ka hoʻomohala ʻana i ke kahua o nā alloys tungsten kālā, e wehe ana i nā mea hou a me nā hoʻomaikaʻi. Ke ʻimi mau nei nā ʻepekema a me nā ʻenekinia i nā ala e hoʻomaikaʻi ai i kāna mau waiwai a hoʻonui i kāna ʻano noi.

I ka hopena, kū ke kala tungsten alloy i mea hōʻike i ke akamai o ke kanaka i ka ʻepekema waiwai, e hāʻawi ana i nā hoʻonā i kekahi o nā pilikia ʻenehana a me nā pilikia ʻenehana. ʻO kāna hui pū ʻana o nā waiwai e lilo ia i mea waiwai nui i nā ʻoihana like ʻole, e hana ana i ka honua hou me kona alo a me kona hiki.

ʻO ka hana ʻana o ke kala tungsten alloy:

ʻO ka pauka Metallurgy:

He ala maʻamau kēia. Hoʻohui ʻia nā pauka maikaʻi o ke kālā a me ka tungsten i nā ʻāpana i makemake ʻia. Hoʻopili ʻia ka hui ʻana ma lalo o ke kaomi kiʻekiʻe e hana i kahi ʻōmaʻomaʻo. Hoʻopili ʻia kēia paʻi ma hope i kahi wela kiʻekiʻe e hoʻohui i nā ʻāpana a hana i kahi huila paʻa. No ka laʻana, i kekahi mau hihia, hiki ke wili mua ʻia nā pauka e hōʻoia i kahi hui like ʻole.

Hoʻopaʻa ʻia i ka mahu (CVD):

Ma kēia ʻano, hoʻokomo ʻia nā precursors kinoea me ke kālā a me ka tungsten i loko o kahi keʻena pane. Ma lalo o nā kūlana kūikawā o ka mahana a me ke kaomi, hana nā precursors a waiho ma luna o kahi substrate e hana i ka papa alloy. Hāʻawi kēia ʻenehana i ka mana pololei o ka haku mele a me ka microstructure.

Electroplating:

Hiki ke hana ʻia ke kala tungsten alloy ma o ka electroplating. Hoʻokomo ʻia kahi substrate tungsten i loko o kahi electrolyte i loaʻa nā ion kālā. Ma ka hoʻohana ʻana i ke au uila, waiho ʻia ke kālā ma luna o ka ʻili tungsten, e hana ana i ka papa alloy. Hiki ke hoʻololi i kēia kaʻina hana no ka loaʻa ʻana o nā mānoanoa like ʻole a me nā haku mele o ka uhi ʻana.

Sinter-HIP (Hot Isostatic Pressing):

Hoʻopili mua ʻia ka hui ʻana o ka pauka a laila hoʻokomo ʻia i ke kaomi isostatic wela. Kōkua kēia i ka hoʻopau ʻana i ka porosity a me ka hoʻomaikaʻi ʻana i ka nui a me nā waiwai mechanical o ka alloy fabricated.

ʻO ke koho ʻana i ke ʻano hana e pili ana i nā ʻano like ʻole e like me nā waiwai i makemake ʻia o ka alloy hope, ke ʻano a me ka nui o ka mea e hana ʻia, a me ka pae hana. Loaʻa i kēlā me kēia ʻano ka maikaʻi a me nā palena, a pinepine, hiki ke hoʻohana ʻia ka hui ʻana o kēia mau ʻenehana no ka loaʻa ʻana o nā hopena maikaʻi loa.

He nui nā noi kikoʻī ma muli o kāna mau waiwai kūʻokoʻa:

Hoʻopili uila:

● I loko o nā kaha kaapuni kiʻekiʻe-voltage, kahi e hiki ai ke hoʻopaʻa i nā au nui a me ka hoʻololi pinepine ʻana me ka ʻole o ka ʻaʻahu nui a i ʻole ka hōʻino.

● I nā relays a me nā mea hoʻopili no nā ʻōnaehana mana ʻoihana, e hāʻawi ana i ka pilina uila hilinaʻi a me ke ola lōʻihi.

Nā uila uila:

● No ka mīkini hoʻokuʻu uila (EDM), kahi o kona conductivity kiʻekiʻe a me ke kū'ē ʻana e ʻaʻahu e hōʻoia i ka wehe pono ʻana a me ka pono.

● I ka arc welding electrodes, e kaumaha ana maikai wela dissipation a me ka lōʻihi.

Nā ʻāpana Aerospace:

● Ma nā ʻāpana o nā ʻenekini mokulele a me nā ʻōnaehana mokulele e koi ana i nā mea me ke kūpaʻa wela kiʻekiʻe a me ka ikaika mechanical.

Hooponopono wela:

● Ke hāʻule ka wela i nā mea uila, hoʻokele maikaʻi a hoʻopau i ka wela.

Mea Paahana a Make:

● No ka hoʻopaʻa ʻana a me ka hana ʻana i nā hana, ʻoi aku ka nui o nā noi i mea koʻikoʻi ka paʻakikī kiʻekiʻe.

Nā mea nani:

● Ma muli o kona hiʻohiʻona maikaʻi a me ka lōʻihi, hiki ke hoʻohana ʻia i ka hana ʻana i nā ʻāpana mea nani.

No ka laʻana, i ka ʻoihana kaʻa, hoʻohana ʻia nā mea hoʻopili kālā tungsten alloy i nā mīkini hoʻomaka e hōʻoia i ka hoʻomaka ʻana o ka mīkini ma lalo o nā kūlana like ʻole. Ma ke kahua o ke kelepona, hoʻohana ʻia ia i nā hoʻololi kiʻekiʻe e mālama i ka pono o ka hōʻailona a hōʻemi i ka nalowale o ka hōʻailona.

Waiwai Tungsten Alloy Kala

| Code No. | Huina Kemika % | Nā waiwai mīkini | ||||||

| Ag | haumia≤ | W | ʻO ka mānoanoa (g/cm3 ) ≥ | ʻoʻoleʻa HB ≥ | RES (μΩ·cm) ≤ | ʻO ka hoʻokō IACS/ % ≥ | TRS/ Mpa ≥ | |

| AgW(30) | 70±1.5 | 0.5 | Kaulike | 11.75 | 75 | 2.3 | 75 | |

| AgW(40) | 60±1.5 | 0.5 | Kaulike | 12.40 | 85 | 2.6 | 66 | |

| AgW(50) | 50±1.5 | 0.5 | Kaulike | 13.15 | 105 | 3.0 | 57 | |

| AgW(55) | 45±2.0 | 0.5 | Kaulike | 13.55 | 115 | 3.2 | 54 | |

| AgW(60) | 40±2.0 | 0.5 | Kaulike | 14.00 | 125 | 3.4 | 51 | |

| AgW(65) | 35±2.0 | 0.5 | Kaulike | 14.50 | 135 | 3.6 | 48 | |

| AgW(70) | 30±2.0 | 0.5 | Kaulike | 14.90 | 150 | 3.8 | 45 | 657 |

| AgW(75) | 25±2.0 | 0.5 | Kaulike | 15.40 | 165 | 4.2 | 41 | 686 |

| AgW(80) | 20±2.0 | 0.5 | Kaulike | 16.10 | 180 | 4.6 | 37 | 726 |